About Hinah Powder Coating

Complete Powder Gun Components

Hinah Powder Coating Technology Co., Ltd. is a professional company engaged in the research and development, production, sales and technical services of thermosetting powder coatings.

Relying on the factory’s experience in manufacturing and servicing powder spraying equipment, we have established a strong powder spraying gun laboratory and have developed and produced several of our own powder spraying gun series. And we have standardized the complete set of accessories.It has 12 advanced professional production lines and 6 R&D test lines. The annual production capacity is 10,000 tons.

- Best price for best results

- Lowest possible maintenance costs

- Ultra-long service life

- Worldwide Shipping

- Guidelines for use

- 24*7 Service Online

- Extensive accessories

Factory Show

We are a professional powder coating guns manufacturer.

We have very rich experience, powder coating for wheel, powder coating for metal, powder coating for profile, powder coating for cars etc.

No matter you need a wholesaler supplier, or custom powder coating equipments. We can all help.

Send inquiry to get an instant quote now!

Certificate of Honor

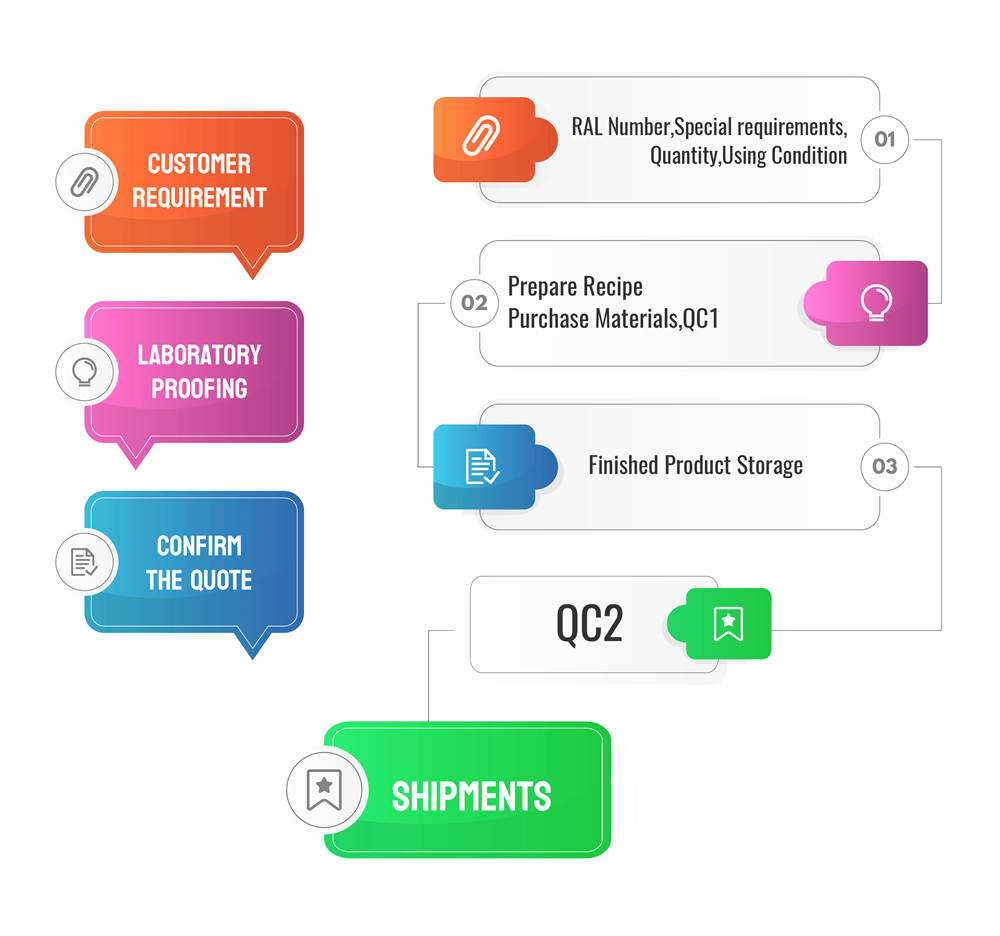

Order Process

Some FAQ You May Concern

The price of a simple powder coating system usually depends on the components of the system, the brand, and the functional requirements. Typically, simple systems include basic equipment such as spray guns, power controllers, air compressors, and powder coating recovery units. Depending on the configuration, prices will vary.

For a small or basic powder coating system, prices range from a few thousand to over ten thousand USD. This price is usually for a small studio or small batch production where the system configuration is simple and the functionality is relatively basic.

For medium-sized businesses or systems that require higher performance and more precise control, the price can be higher, usually in the range of 2,000 to 10,000 $. These systems typically include features such as more efficient spray guns, optimized air systems, and automatic powder recovery.

The final price will vary depending on the customer’s specific needs, options (e.g. booths, ovens, etc.) and supplier. If you have specific requirements or needs, it is recommended that you speak directly with the supplier to get the most accurate quote.

Powder coating gun is a professional tool used for powder coating, which is widely used for coating metal, plastic and other surfaces. Its main function is to evenly apply powder coating to the surface of the workpiece through electrostatic principles, resulting in a durable and uniform coating.

The working principle of a powder coating gun is usually based on electrostatic spraying technology, whereby the gun attracts the powder coating particles to the surface of the target object by means of an electrical charge. In this process, the paint particles are sprayed through the gun at high speeds and are attracted to the surface of the object by an electric field to form a uniform coating. Spray guns are usually equipped with sophisticated controls that regulate the powder flow, spray angle and spray distance to ensure uniformity and quality of the coating.

Depending on the application requirements, powder coating guns are available in a variety of different models and sizes. For example, manual guns are suitable for small batch production or restoration work, while automatic guns are typically used in large-scale production lines with higher efficiency and precision. High-end spray guns may also be equipped with an intelligent control system that can automatically adjust spraying parameters to ensure optimal coating results.

The advantages of powder coating guns are:

- Efficient and environmentally friendly: Powder coatings have no solvents and do not produce harmful gases during the spraying process, which meets the requirements of environmental protection.

- Durable coating: Powder coating has excellent corrosion resistance, abrasion resistance and UV resistance.

- Good coating effect: It can provide a uniform and strong coating, which reduces paint waste and improves productivity.

Powder coating systems are widely recognized as one of the most environmentally friendly coating methods and are environmentally friendly in several ways:

No Solvents, No Volatile Organic Compounds (VOCs): Unlike traditional liquid coatings, powder coatings contain no solvents or Volatile Organic Compounds (VOCs), which means that no harmful gases are emitted during the spraying process, reducing air pollution and complying with strict environmental regulations.

Efficient recycling: Powder coating systems are often equipped with a powder recycling unit. Excess powder coating can be efficiently recycled and reused, reducing waste and environmental burden. This recycling rate can be as high as 90% or more, effectively saving coating materials.

Reduced waste: With no solvents and less waste, powder coating systems produce relatively little waste, reducing environmental pollution and disposal costs.

Low Energy Consumption: Compared to traditional painting processes, powder coating systems are typically lower in energy consumption. For example, during the spraying process, the spray gun can accurately spray the powder coating onto the workpiece through electrostatic adsorption, which reduces the waste of paint and also helps to save energy.

Safety: Powder coating itself is solid, non-flammable and contains no hazardous substances, making it safer to handle compared to liquid coatings, reducing occupational hazards and safety risks.

In conclusion, powder coating systems not only provide high-quality coating results, but have also become the preferred coating method in many industries due to their environmentally friendly nature. If you are concerned about environmental protection and sustainability, powder coating systems are definitely a very suitable choice.

Yes, powder coating systems are ideally suited for use on many different products, especially in applications that require a durable, high-quality coating. Whether it’s metal, plastic, aluminum, or a variety of other materials, powder coating systems provide excellent results.

Here are some common areas where powder coating systems can be applied:

Metal Products: Powder coating performs particularly well on metal surfaces, especially on materials such as steel, aluminum alloys and stainless steel. It provides a coating that is highly resistant to corrosion and weathering, making it ideal for metal products that are used outdoors or in harsh environments, such as automotive parts, furniture, and building structures.

Plastic: Powder coating systems can also be applied to certain plastic products, especially specially treated plastic materials. It can provide a strong protective layer on the plastic surface, improving the appearance and durability of the product.

Home Appliances: For example, in the shells of refrigerators, washing machines, microwave ovens and other home appliances, the uniform coating provided by powder coating not only enhances the aesthetics, but also increases the resistance to scratches and corrosion.

Automotive parts: Powder coating is widely used in the automotive industry, especially for body frames, wheels and engine parts. It provides good UV and corrosion resistance and increases the durability and appearance quality of automotive parts.

Furniture and Decorative Products: Powder coating is ideal for surface coating of furniture, lamps, door and window frames and other products. It provides a durable coating while avoiding the problems of sagging and odor that can be associated with traditional liquid coatings.

Industrial Equipment: Many mechanical devices and tools, especially those subject to friction and heavy loads, powder coating provides excellent abrasion and oxidation resistance, making it ideal for application as a protective coating on industrial equipment.

The Reason Why Hinah Is The Best For You

Fast Delivery

Fast delivery through distribution channels and a network of distributors is the first step in our fast reach.

Best Price

A strong manufacturing industry is a guarantee of competitiveness, a complete ecology is a guarantee of price.

Warranty Period

The warranty cycle makes investment a solid one, and the high quality is the basis of the warranty. Dare to warranty, quality assurance.

Powder guns and kits from China, the top choice for the best value for money.

Follow us on our Channel!

@Hinah powder coating

sales@hinahpowdercoating.com

Phone(WhatsApp/WeChat)

+ 86 -186 3213 8668